Seamless Steel Pipe ASTM A106 B NACE MR 0175 12IN SCH160

Seamless Steel pipe A106 B NACE MR 0175 323 8x25 4mmASTM A106 A 106MStandard Covers Seamless Carbon Steel Pipe for

Product Introduction

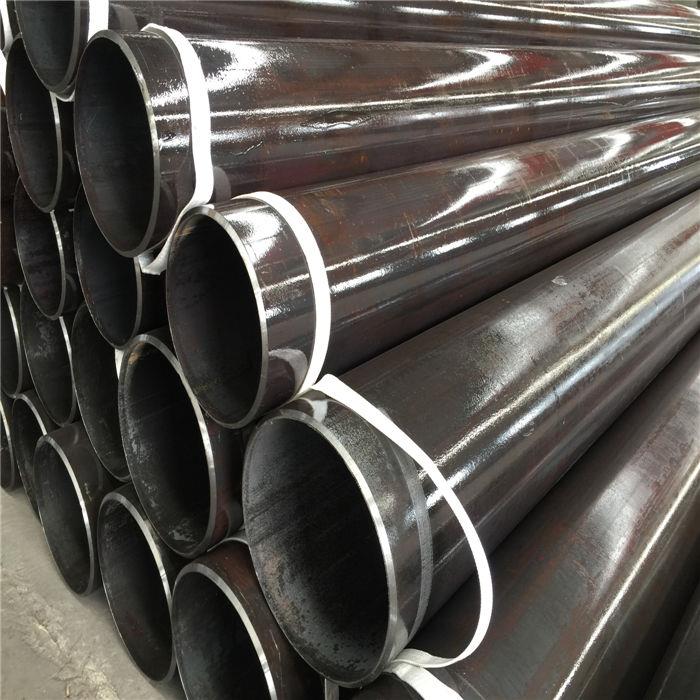

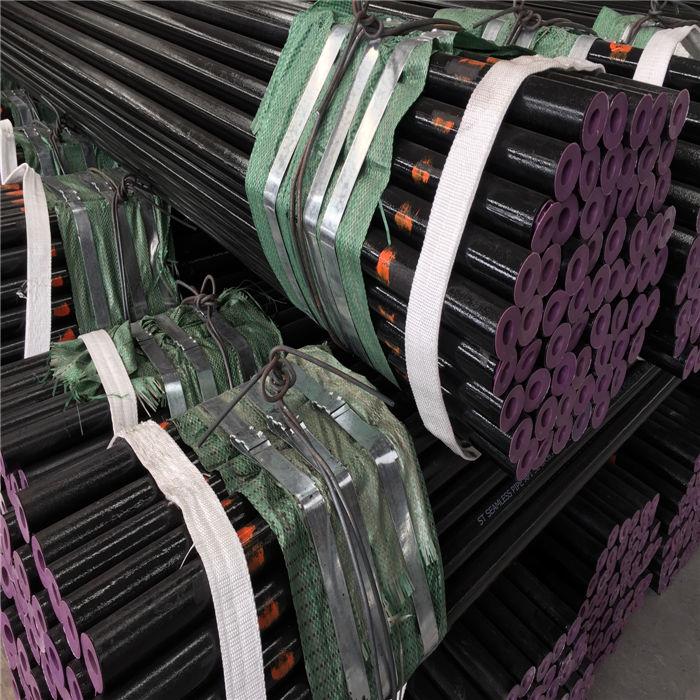

Seamless Steel pipe A106 B NACE MR 0175 323.8x25.4mm

ASTM A106/A 106M Standard Covers Seamless Carbon Steel Pipe for high-temperature service in NPS 1/8 TO NPS 48 (DN6 to DN1200) inclusive, with nominal (average) wall thickness as given in ASME B 36.10M. It shall be permissible to furnish pipe having other dimensions provided such pipe complies with all other requirements of this specification. Pipe ordered under this specification shall be suitable for bending, flanging, and similar forming operations, and for welding. When the steel is to be welded, it is presupposed that a welding procedure suitable to the grade of steel and intended use or service will be utilized.

ASTM A106/A 106M covers both seamless hot-finished and cold-finished pipe in sizes up to and including NPS 1/8 TO NPS 42 outside diameter for round tubes with wall thicknesses as required.

Description Name: ASTM A106B Seamless pipe, ASTM A106 GR. B Seamless pipe, A106 GR. B tubes

Size: 21.3mm-1067mm

Schedule: SCH10, SCH20, SCH40, SCH80, SCH160 SCHXXS FOR Thickness

Length: Single random length/ Double random length or as customer’s actual request

Grade: GR. A, GR. B, GR. C

Condition: HF-Hot Finished, CD-Cold DRAWN, HE-Hot Expand

ASTM A106 Gr. B Seamless Carbon Steel Pipe Chemical Composition(%):

| Standard | Grade | Chemical Components (%) | |||||||

| C | Si | Mn | P | S | Mo | Cr | V | ||

| ASTM A106 | A | ≤0.25 | ≥01.0 | 0.27-0.93 | ≤0.035 | ≤0.035 | ≤0.15 | ≤0.40 | ≤0.08 |

| B | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.15 | ≤0.40 | ≤0.08 | |

| C | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.15 | ≤0.40 | ≤0.08 | |

ASTM A106 Gr. B Seamless Carbon Steel Pipe Mechanical Tests Required

| Standard | Grade | Mechanical properties | ||

| Tensile Strength (Mpa) |

Yield Strength (Mpa) |

Elongation (%) |

||

| ASTM A106 | A | ≥330 | ≥205 | ≥35 |

| B | ≥415 | ≥240 | ≥30 | |

| C | ≥485 | ≥275 | ≥30 | |

NACE MR 0175 or ISO 15156 standard

Steel pipe and related fittings which are made from the NACE material (complied with NACE MR 0175 or ISO 15156 standard). We call them NACE pipe, or NACE pipe fittings. These products are specially used in the oil and gas environments that contain the H2S etc corrosive chemicals.

Carbon and low alloy steel pipes and fittings that complied with NACE MR0175, with stated exceptions, further SSC testing is not required. Nevertheless, any SSC testing that forms part of a materials manufacturing specification shall be carried out successfully and the results reported.

Chemical Composition

For carbon and alloy steel pipes, NACE MR0175 has limits for content Sulfur (S ≤ 0.002%), Phosphorus (P ≤ 0.020%) and Carbon (C ≤ 0.10%).

Mechanical Strength

Mechanical properties of tensile strength, and yield strength is same with general pipes referred to corresponding standards.

NACE Test Methods

For sour service steel pipe, plate, fittings, commonly there are two test methods referred NACE. HIC and SSC.

HIC is Hydrogen Induced Cracking. HIC test is a mandatory test for NACE pipe and fittings. But if there is certificate to proof the material (Raw material for making pipes or fittings) comply to NACE MR0175, then there is no need to do this test again.

SSC is Sulfide Stress Cracking. SSC test is a long time lasting experiment. The test is specially to alloy steel, to put test material in corrosion environment plus with constant pulling force (Under situation of working force and metal inside force). In these two factors (Corrosion + Force) affects, material havs the brittle rupture. So this is SSC cracking.

(SSC cracking is one of the most harmful corrosion types, during corrosion, if there is any small cracks, the broken speed is far more soon than other type of corrosion. So SSC corrosion is an “Corrosion Disaster”. This happened in Bridge damage, Airplane accidents, boiler tank explosion. These are bring big loss for people’s life and property. Other than this, power station, Ship, boiler tank, petroleum industries all happened SSC accidents.)

NACE MR0175 pipe and fittings Applications

The material shall be used in water-containing liquid and media which include all kinds of gas, or H2S containing crude oil, the H2S absolute partial pressure ≥0.0003 Mpa (0.05 psia).

On the other hand, under these conditions there is no need apply to MR0175. (It’s up to users.)

a. Low pressure gas: the total pressure is lower than 0.4 MPa (65 psia).

b. Low pressure gas and oil multi phases media: the total pressure is lower than 1.83 MPa.

MR0175 standards of general material requirements for selecting of cracking-resistant material, cracking-resistant carbon and low-alloys steels, cast irons, cracking-resistant alloys and other alloys. And details requirements for H2S containing equipment.

Material Cost of NACE MR0175 than General pipe

The price for NACE pipe itself is not too much higher than general steel pipe, (Especially for API 5L pipe or ASTM A106 pipe, the price is higher but not more than 100 dollars).

On the other hand, the hard and expensive part is HIC and SSC test fees. If the quantity is very less, and there is no stock available, it is almost impossible to get this material.

My company hot sale steel pipe and pipe fittings:

API 5L X65, X70 PSL2 LSAW welded pipes, (20” to 60” sch40, sch80, sch160),

API 5CT seamless casing, and tubing, (2 3/8” to 20” K55, J55, N80, L80, P110),

You Might Also Like

-

large diameter Seamless Line Pipes API 5L GR.B 1016x25.4 mm 6 m length

-

St37 Seamless Tube 88.9mm Diameter

-

Seamless Steel Pipe ASTM A106 B NACE MR 0175 12IN SCH160

-

Seamless Line Pipe API 5L GR.B 24INCH SCH40 12M Length

-

Seamless Pipe 2inch Idimeter XXS 6 M LENGTH Export

-

Seamless Pipe ASTM A106 C 10IN Diameter XS 12M Length

Send Inquiry