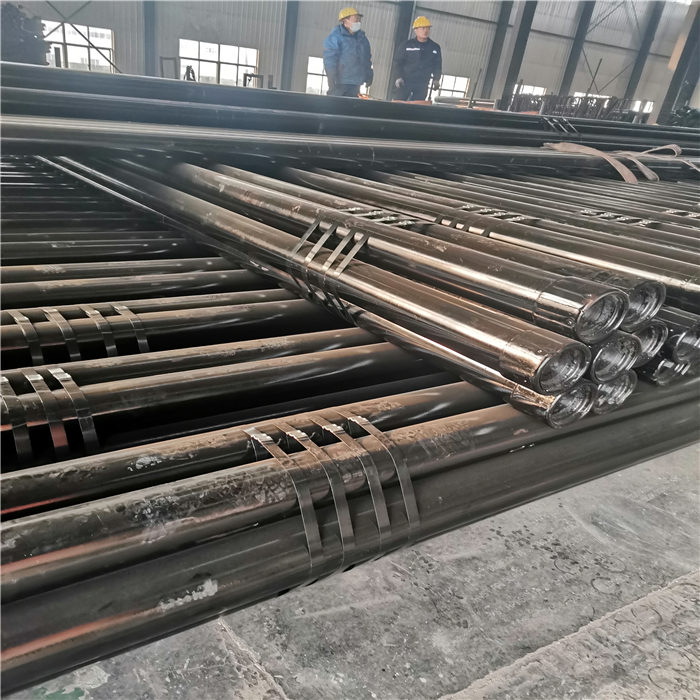

API 5CT J55 Tubing 3-1/2" 12.70 PPF NU R2 length

API 5CT NJ55 Casing Tubingis a API 5CT Oil Casing Pipe & mainly used for oil well drilling We manufacture API 5We manufacture API 5CT J55 Casing Tubing in accordance with the API 5CT standard, it is available as short thread type and long thread typ

Product Introduction

-

API 5CT J55 Casing Tubing is a API 5CT Oil Casing Pipe & mainly used for oil well drilling. We manufacture API 5CT J55 Casing Tubing in accordance with the API 5CT standard, it is available as short thread type and long thread type supplied with their couplings.

-

According to American Petroleum Institute Standard API SPEC 5CT1988 1st edition, the steel grade of API 5CT oil casing pipe can be divided into ten types, including H-40, J-55, K-55, N-80, C-75, L-80, C-90, C-95, P-110 and Q-125. We supply the casing pipe & API 5CT J55 Casing Tubing accompanied with thread and coupling, or we offer our product in accordance with the following forms for option.

-

API 5CT Casing Tubing Chemical Composition, Mass Fraction (%)

| Group | Grade | Type | C | Mn | Mo | Cr | Ni max. | Cu max. | P max. | S max. | Si max. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min. | max. | min. | max. | min. | max. | min. | max. | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

|

1 |

H40 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.03 |

0.03 |

- |

|

J55 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.03 |

0.03 |

- |

|

|

K55 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.03 |

0.03 |

- |

|

|

N80 |

1 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.03 |

0.03 |

- |

|

|

N80 |

Q |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.03 |

0.03 |

- |

|

|

R95 |

- |

- |

0.45 c |

- |

1.9 |

- |

- |

- |

- |

- |

- |

0.03 |

0.03 |

0.45 |

|

|

2 |

M65 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.03 |

0.03 |

- |

|

L80 |

1 |

- |

0.43 a |

- |

1.9 |

- |

- |

- |

- |

0.25 |

0.35 |

0.03 |

0.03 |

0.45 |

|

|

L80 |

9Cr |

- |

0.15 |

0.3 |

0.6 |

0.9 |

1.1 |

8 |

10 |

0.5 |

0.25 |

0.02 |

0.01 |

1 |

|

|

L80 |

13Cr |

0.15 |

0.22 |

0.25 |

1 |

- |

- |

12 |

14 |

0.5 |

0.25 |

0.02 |

0.01 |

1 |

|

|

C90 |

1 |

- |

0.35 |

- |

1.2 |

0.25 b |

0.85 |

- |

1.5 |

0.99 |

- |

0.02 |

0.01 |

- |

|

|

T95 |

1 |

- |

0.35 |

- |

1.2 |

0.25 d |

0.85 |

0.4 |

1.5 |

0.99 |

- |

0.02 |

0.01 |

- |

|

|

C110 |

- |

- |

0.35 |

- |

1.2 |

0.25 |

1 |

0.4 |

1.5 |

0.99 |

- |

0.02 |

0.005 |

- |

|

|

3 |

P110 |

e |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 e |

0.030 e |

- |

|

4 |

Q125 |

1 |

- |

0.35 |

1.35 |

- |

0.85 |

- |

1.5 |

0.99 |

- |

0.02 |

0.01 |

- |

|

| a The carbon content for L80 may be increased up to 0.50 % maximum if the product is oil-quenched. b The molybdenum content for Grade C90 Type 1 has no minimum tolerance if the wall thickness is less than 17.78 mm. c The carbon content for R95 may be increased up to 0.55 % maximum if the product is oil-quenched. d The molybdenum content for T95 Type 1 may be decreased to 0.15 % minimum if the wall thickness is less than 17.78 mm. e For EW Grade P110, the phosphorus content shall be 0.020 % maximum and the sulfur content 0.010 % maximum. NL = no limit. Elements shown shall be reported in product analysis. |

|||||||||||||||

API 5CT Casing Tubing Tensile And Hardness Requirements

| Group | Grade | Type | Total elongation under load % | Yield strength MPa | Tensile strength min. MPa | Hardness a max. | Specified wall thickness mm | Allowable hardness variation b HRC | ||

|---|---|---|---|---|---|---|---|---|---|---|

| min. | max . | HRC | HBW | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 1 |

H40 |

- |

0.5 |

276 |

552 |

414 |

- |

- |

- |

- |

|

J55 |

- |

0.5 |

379 |

552 |

517 |

- |

- |

- |

- |

|

|

K55 |

- |

0.5 |

379 |

552 |

655 |

- |

- |

- |

- |

|

|

N80 |

1 |

0.5 |

552 |

758 |

689 |

- |

- |

- |

- |

|

|

N80 |

Q |

0.5 |

552 |

758 |

689 |

- |

- |

- |

- |

|

|

R95 |

- |

0.5 |

655 |

758 |

724 |

- |

- |

- |

- |

|

| 2 |

M65 |

- |

0.5 |

448 |

586 |

586 |

22 |

235 |

- |

- |

|

L80 |

1 |

0.5 |

552 |

655 |

655 |

23 |

241 |

- |

- |

|

|

L80 |

9Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

- |

- |

|

|

L80 |

13Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

- |

- |

|

|

C90 |

1 |

0.5 |

621 |

724 |

689 |

25.4 |

255 |

≤ 12.70 12.71 to 19.04 19.05 to 25.39 ≥ 25.40 |

3.0 4.0 5.0 6.0 |

|

|

T95 |

1 |

0.5 |

655 |

758 |

724 |

25.4 |

255 |

≤ 12.70 12.71 to 19.04 19.05 to 25.39 ≥ 25.40 |

3.0 4.0 5.0 6.0 |

|

|

C110 |

- |

0.7 |

758 |

828 |

793 |

30 |

286 |

≤ 12.70 12.71 to 19.04 19.05 to 25.39. ≥ 25.40 |

3.0 4.0 5.0 6.0 |

|

| 3 |

P110 |

- |

0.6 |

758 |

965 |

862 |

- |

- |

- |

- |

| 4 |

Q125 |

1 |

0.65 |

862 |

1034 |

931 |

b |

- |

≤ 12.70 12.71 to 19.04 ≥ 19.05 |

3.0 4.0 5.0 |

| a In case of dispute, laboratory Rockwell C hardness testing shall be used as the referee method. b No hardness limits are specified, but the maximum variation is restricted as a manufacturing control in accordance with 7.8 and 7.9 of API Spec. 5CT. |

||||||||||

API 5CT Casing Tubing Steel Color Code

| Name | J55 | K55 | N80-1 | N80-Q | L80-1 | P110 |

|---|---|---|---|---|---|---|

| Casing | a bright green band | two bright green bands | a bright red band | a bright red band + a green band | a red band + a brown band | a bright white band |

| Coupling | entire green coupling + a white band | entire green coupling | entire red coupling | entire red coupling + a green band | entire red coupling + a brown band | entire white coupling |

-

-

Available Sizes: 2 3/8″, 2 7/8″ and 3 ½” Outer Diameter

-

Macaroni Tubing: 1 1/4 “ – 2 1/16” Nom.

-

Grades: J55, J55, N80, L80, P110

-

End Finishing: External Upset Ends (EUE), PH6 (and equivalent connections), Flush Joint, Integral Joint (IJ)

-

Specialties:

-

Threading

-

Heat treating

-

External upset

-

Drifting (Full-length, or just ends)

-

Hydrostatic Testing

-

Full third-party inspection capabilities (EMI, SEA, and Weld Line)

-

Couplings – EUE, AB Modified, turned down, special clearance couplings

-

Coating to customer specifications

-

Pup Joints

-

You Might Also Like

-

large diameter Seamless Line Pipes API 5L GR.B 1016x25.4 mm 6 m length

-

St37 Seamless Tube 88.9mm Diameter

-

Seamless Steel Pipe ASTM A106 B NACE MR 0175 12IN SCH160

-

Seamless Line Pipe API 5L GR.B 24INCH SCH40 12M Length

-

Seamless Pipe 2inch Idimeter XXS 6 M LENGTH Export

-

Seamless Pipe ASTM A106 C 10IN Diameter XS 12M Length

Send Inquiry