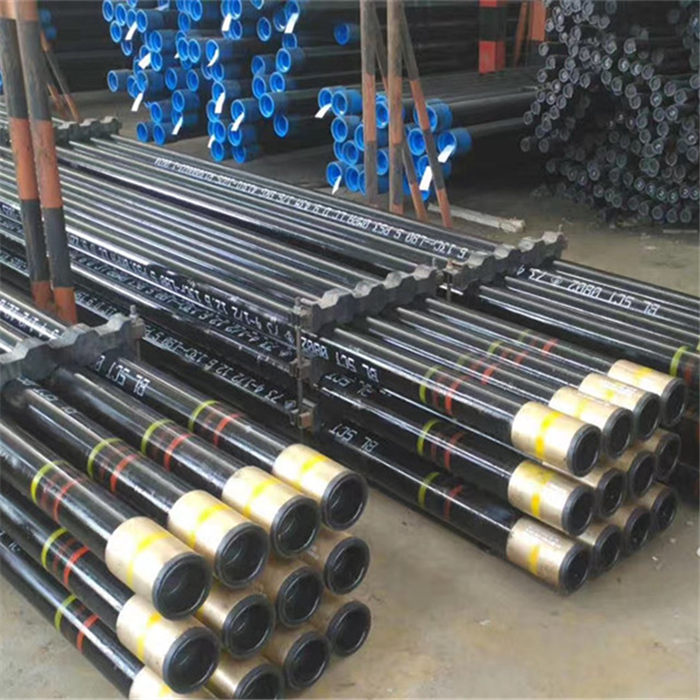

API 5CT N80Q Pup Joint 3, 6, 10M length

Pup joint is kind of seamless pipe with non-standard length to adjust the length of tubular strings to its exac

Product Introduction

Pup joint is kind of seamless pipe with non-standard length to adjust the length of tubular strings to its exact requirement. API 5CT casing and tubing pup joint are produced according to API SPEC 5CT standard. Beyond the standard of oil casing pipe is called pup joint, the main oil casing pup joint material: J55, K55, N80, L80, C90, T95 and P110. We can supply pup joint with good quality.

Pup joint details:

Standard: API SPEC 5CT

Steel Grade: J55/K55/N80/L80/P110/C95

OD of Tubing Joint: From 2-3/8"(60.3mm) to 4.5"(114.60mm);

Pipe end: EUE/NUE

OD of Casing Joint: From 4-1/2"(114.3mm) to 20"(508mm);

Threads: BTC, LTC, STC.

Length: 2,3,4,6,8,10 12 ft (with other lengths available upon request)

Surface treatment: coating

Packing: according to customer specific requirements, by wooden case or wooden pallet.

COVERAGE of API 5CT Tubing & Casing / OCTG:

This International Standard specifies the technical delivery conditions for steel pipes (casing, tubing,plain-end casing liners and pup joints), coupling stock and accessories and establishes requirements for three Product Specification Levels (PSL-1, PSL-2, PSL-3).

Application of API 5CT Tubing & Casing / OCTG:

Tubing is used for extracting oil or gas from wells,while casing for sidewall.Main Steel Grade of API 5CT Tubing & Casing / OCTG:

H40,J55,K55,N80-1,N80-Q,M65,L80-1,L80-9Cr,L80-13Cr,C90,C95,T95,P110,Q125.Pipe type of API 5CT Tubing & Casing / OCTG:

HFW、SMLS

Size of API 5CT Tubing & Casing / OCTG:

1.Tubing(1.050″~4-1/2″)

2.Casing(4-1/2″~20″)

Type of end finish of API 5CT Tubing & Casing / OCTG:

Tubing(P:plain-end; N:non-upset,with threaded and coupled; U:external-upset,with threaded and coupled; I:integral joint)

Casing(P:plain-end; L:long round thread; S:short round thread; B:buttress thread)

|

Chemical Composition of API 5CT Tubing & Casing / OCTG: |

|||||||||

|

Grade |

C |

Mn |

Mo |

Cr |

Ni |

Cu |

P |

S |

Si |

|

min(max) |

max |

min (max) |

min (max) |

max |

max |

max |

max |

max |

|

|

H40 |

/ |

/ |

/ |

/ |

/ |

/ |

0.030 |

0.030 |

/ |

|

J55 |

/ |

/ |

/ |

/ |

/ |

/ |

0.030 |

0.030 |

/ |

|

K55 |

/ |

/ |

/ |

/ |

/ |

/ |

0.030 |

0.030 |

/ |

|

N80 Type1 |

/ |

/ |

/ |

/ |

/ |

/ |

0.030 |

0.030 |

/ |

|

N80Q |

/ |

/ |

/ |

/ |

/ |

/ |

0.030 |

0.030 |

/ |

|

M65 |

/ |

/ |

/ |

/ |

/ |

/ |

0.030 |

0.030 |

/ |

|

L80 Type1 |

0.43 |

1.90 |

/ |

0.25 |

0.35 |

0.030 |

0.030 |

0.45 |

|

|

L80 9Cr |

0.15 |

0.60 |

0.90(1.1) |

8.0(10) |

0.50 |

0.25 |

0.020 |

0.010 |

1.00 |

|

L80 13Cr |

0.15(0.22) |

1.00 |

/ |

12(14) |

0.50 |

0.25 |

0.020 |

0.010 |

1.00 |

|

C90 Type1 |

0.35 |

1.20 |

0.25(0.85) |

1.50 |

0.99 |

/ |

0.020 |

0.010 |

/ |

|

C90 Type2 |

0.50 |

1.90 |

NL |

NL |

0.99 |

/ |

0.030 |

0.010 |

/ |

|

C95 |

0.45 |

1.90 |

/ |

/ |

/ |

/ |

0.030 |

0.030 |

0.45 |

|

T95 Type1 |

0.35 |

1.20 |

0.25(0.85) |

0.4(1.5) |

0.99 |

/ |

0.020 |

0.010 |

/ |

|

T95 Type2 |

0.5 |

1.90 |

/ |

/ |

0.99 |

/ |

/ |

/ |

/ |

|

P110 |

/ |

/ |

/ |

/ |

/ |

/ |

0.030 |

0.030 |

/ |

|

Q125 Type1 |

0.35 |

1.35 |

0.85 |

1.50 |

0.99 |

/ |

0.020 |

0.010 |

/ |

|

Q125 Type2 |

0.35 |

1.00 |

NL |

NL |

0.99 |

/ |

0.020 |

0.020 |

/ |

|

Q125 Type3 |

0.50 |

1.90 |

NL |

NL |

0.99 |

/ |

0.030 |

0.010 |

/ |

|

Q125 Type4 |

0.50 |

1.90 |

NL |

NL |

0.99 |

/ |

0.030 |

0.020 |

/ |

|

Size |

Weight |

Outside Diameter |

Wall Thickness |

End Finish |

||||||

|

Grade |

||||||||||

|

in |

mm |

in |

mm |

J55K55 |

L80 |

N80 |

C90T95 |

P110 |

||

|

4 1/2 |

9.50 |

4.500 |

114.3 |

0.205 |

5.21 |

PS |

– |

– |

– |

– |

|

10.50 |

0.224 |

5.69 |

PSB |

– |

– |

– |

– |

|||

|

11.60 |

0.250 |

6.35 |

PSLB |

PLB |

PLB |

PLB |

PLB |

|||

|

13.50 |

0.290 |

7.37 |

– |

PLB |

PLB |

PLB |

PLB |

|||

|

15.10 |

0.337 |

9.56 |

– |

– |

– |

– |

PLB |

|||

|

5 |

11.50 |

5.00 |

127.00 |

0.220 |

5.59 |

PS |

– |

– |

– |

– |

|

13.00 |

0.253 |

6.43 |

PSLB |

– |

– |

– |

– |

|||

|

15.00 |

0.296 |

7.52 |

PSLB |

PLB |

PLB |

PLBE |

PLB |

|||

|

18.00 |

0.362 |

9.19 |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

21.40 |

0.437 |

11.10 |

– |

PLB |

PLB |

PLB |

PLB |

|||

|

23.20 |

0.478 |

12.14 |

– |

PLB |

||||||

|

24.10 |

0.500 |

12.70 |

– |

PLB |

||||||

|

5 1/2 |

14.00 |

5.500 |

139.7 |

0.244 |

6.20 |

PS |

– |

– |

– |

– |

|

15.50 |

0.275 |

6.98 |

PSLB |

– |

– |

– |

– |

|||

|

17.00 |

0.304 |

7.72 |

PSLB |

PLB |

PLB |

PLBE |

PLB |

|||

|

20.00 |

0.361 |

9.17 |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

23.00 |

0.415 |

10.54 |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

6 5/8 |

20.00 |

6.625 |

168.28 |

0.288 |

7.32 |

PSLB |

– |

– |

– |

– |

|

24.00 |

0.352 |

8.94 |

PSLB |

PLB |

PLB |

PLBE |

PLB |

|||

|

28.00 |

0.417 |

10.59 |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

32.00 |

0.475 |

12.06 |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

7 |

17.00 |

7.00 |

177.80 |

0.231 |

5.87 |

– |

– |

– |

– |

– |

|

20.00 |

0.272 |

6.91 |

PS |

– |

– |

– |

– |

|||

|

23.00 |

0.317 |

8.05 |

PSLB |

PLB |

PLB |

PLBE |

– |

|||

|

26.00 |

0.362 |

9.19 |

PSLB |

PLB |

PLB |

PLBE |

PLB |

|||

|

29.00 |

0.408 |

10.36 |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

32.00 |

0.453 |

11.51 |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

35.00 |

0.498 |

12.65 |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

38.00 |

0.540 |

13.72 |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

7 5/8 |

24.00 |

7.625 |

193.68 |

0.300 |

7.62 |

– |

– |

– |

– |

– |

|

26.40 |

0.328 |

8.33 |

PSLB |

PLB |

PLB |

PLBE |

PLB |

|||

|

29.70 |

0.375 |

9.52 |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

33.70 |

0.430 |

10.92 |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

39.00 |

0.500 |

12.70 |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

42.80 |

0.562 |

14.27 |

– |

PLB |

PLB |

PLB |

PLB |

|||

|

45.30 |

0.595 |

15.11 |

– |

PLB |

PLB |

PLB |

PLB |

|||

|

47.10 |

0.625 |

15.88 |

– |

PLB |

PLB |

PLB |

PLB |

|||

|

8 5/8 |

24.00 |

8.625 |

219.08 |

0.264 |

6.71 |

PS |

– |

– |

– |

– |

|

28.00 |

0.304 |

7.72 |

– |

– |

– |

– |

– |

|||

|

32.00 |

0.352 |

8.94 |

PSLB |

– |

– |

– |

– |

|||

|

36.00 |

0.400 |

10.16 |

PSLB |

PLB |

PLB |

PLBE |

PLB |

|||

|

40.00 |

0.450 |

11.43 |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

44.00 |

0.500 |

12.70 |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

49.00 |

0.557 |

14.15 |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

9 5/8 |

32.30 |

9.625 |

244.48 |

0.312 |

7.92 |

– |

– |

– |

– |

– |

|

36.00 |

0.352 |

8.94 |

PSLB |

– |

– |

– |

– |

|||

|

40.00 |

0.395 |

10.03 |

PSLB |

PLB |

PLB |

PLBE |

– |

|||

|

43.50 |

0.435 |

11.05 |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

47.00 |

0.472 |

11.99 |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

53.50 |

0.545 |

13.84 |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

58.40 |

0.595 |

15.11 |

– |

PLB |

PLB |

PLB |

PLB |

|||

|

10 3/4 |

32.75 |

10.75 |

273.05 |

0.279 |

7.09 |

– |

– |

– |

– |

– |

|

40.50 |

0.350 |

8.89 |

PSB |

– |

– |

– |

– |

|||

|

15.50 |

0.400 |

10.16 |

PSB |

– |

– |

– |

– |

|||

|

51.00 |

0.450 |

11.43 |

PSB |

PSB |

PSB |

PSBE |

PSB |

|||

|

55.50 |

0.495 |

12.57 |

– |

PSB |

PSB |

PSBE |

PSB |

|||

|

60.70 |

0.545 |

13.84 |

– |

– |

– |

PSBE |

PSB |

|||

|

65.70 |

0.595 |

15.11 |

– |

– |

– |

PSB |

PSB |

|||

|

13 3/8 |

48.00 |

13.375 |

339.73 |

0.330 |

8.38 |

– |

– |

– |

– |

– |

|

54.50 |

0.380 |

9.65 |

PSB |

– |

– |

– |

– |

|||

|

61.00 |

0.430 |

10.92 |

PSB |

– |

– |

– |

– |

|||

|

68.00 |

0.480 |

12.19 |

PSB |

PSB |

PSB |

PSB |

PSB |

|||

|

72.00 |

0.514 |

13.06 |

– |

PSB |

PSB |

PSB |

PSB |

|||

|

16 |

65.00 |

16 |

406.40 |

0.375 |

9.53 |

– |

– |

– |

– |

– |

|

75.00 |

0.438 |

11.13 |

PSB |

– |

– |

– |

– |

|||

|

84.00 |

0.495 |

12.57 |

PSB |

– |

– |

– |

– |

|||

|

109.00 |

0.656 |

16.66 |

P |

P |

P |

– |

P |

|||

|

18 5/8 |

87.50 |

18.625 |

473.08 |

0.435 |

11.05 |

PSB |

– |

– |

– |

– |

|

20 |

94.00 |

20 |

508.00 |

0.438 |

11.13 |

PSLB |

– |

– |

– |

– |

|

106.50 |

0.500 |

12.70 |

PSLB |

– |

– |

– |

– |

|||

|

133.00 |

0.635 |

16.13 |

PSLB |

– |

– |

– |

– |

|||

You Might Also Like

-

large diameter Seamless Line Pipes API 5L GR.B 1016x25.4 mm 6 m length

-

St37 Seamless Tube 88.9mm Diameter

-

Seamless Steel Pipe ASTM A106 B NACE MR 0175 12IN SCH160

-

Seamless Line Pipe API 5L GR.B 24INCH SCH40 12M Length

-

Seamless Pipe 2inch Idimeter XXS 6 M LENGTH Export

-

Seamless Pipe ASTM A106 C 10IN Diameter XS 12M Length

Send Inquiry