Differences Between LSAW pipes, SSAW pipe and ERW pipes

LSAW, SSAW, and ERW Pipes Comparison

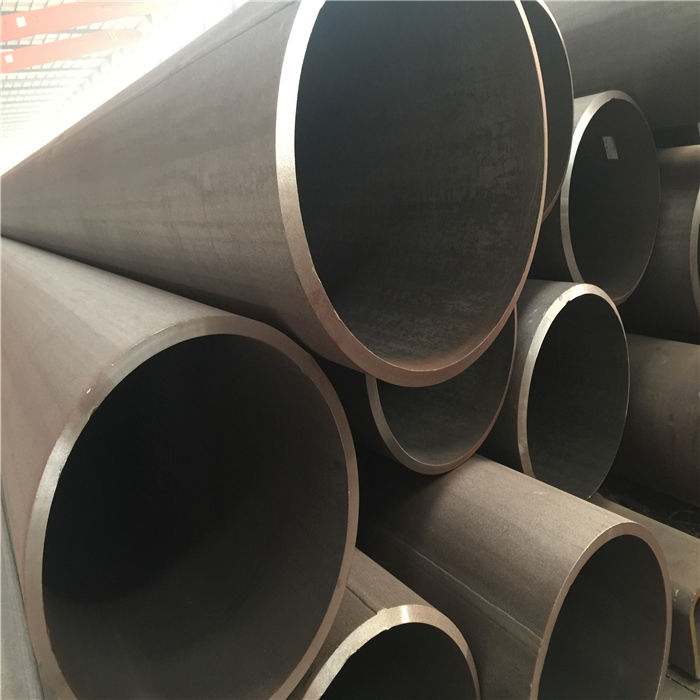

LSAW Pipe (Longitudinal Submerged Arc-Welding Pipe), also called SAWL pipe. It is taking the steel plate as raw material, molding hot-rolled coil plate steel into a cylinder and joining the ends together by double-sided submerged arc welding in a straight line. This creates a pipe welded longitudinally. Through this process the LSAW steel pipe will get excellent ductility, weld toughness, uniformity, plasticity and great sealing.

The LSAW pipe diameter range is larger than ERW, normally from 16 inch to 60 inch, 406mm to 1500mm. Good performances on high pressure resistance, and low-temperature corrosion resistance.

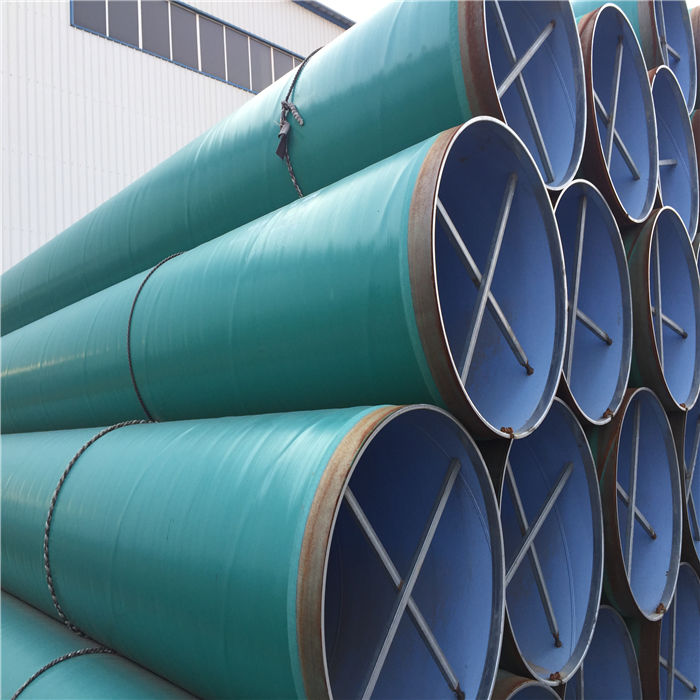

SSAW Pipe (Spiral Submerged Arc-Welding Pipe), also called HSAW pipe (Helical SAW), SSAW steel pipe is formed by rolling and welding a steel strip in a helix or spiral direction, making the weld seam in a spiral line. The spiral welded process makes it possible to create large diameter options.

SSAW pipe is using the same welding technology with LSAW pipe. Differently SSAW pipe is spiral welded. Manufacturing process is rolling the steel strip, to make the rolling direction have an angle with the direction of the pipe center and welding. and LSAW pipe is longitudinally welded.

The SSAW pipe diameter range is from 20 inch to 150 inch, 406 mm to 4000 mm.The advantage thing is we can get the different diameter of SSAW pipes with the same size of the steel strip, there is a wide application for the raw material steel strip, and welding seam should avoid the primary stress, good performances to bear the stress.

Spiral steel pipes are mainly used for low-pressure fluid transmissions such as pipelines on offshore platforms, petrochemical industry plants or shipyards as well as civil construction and pile driving.

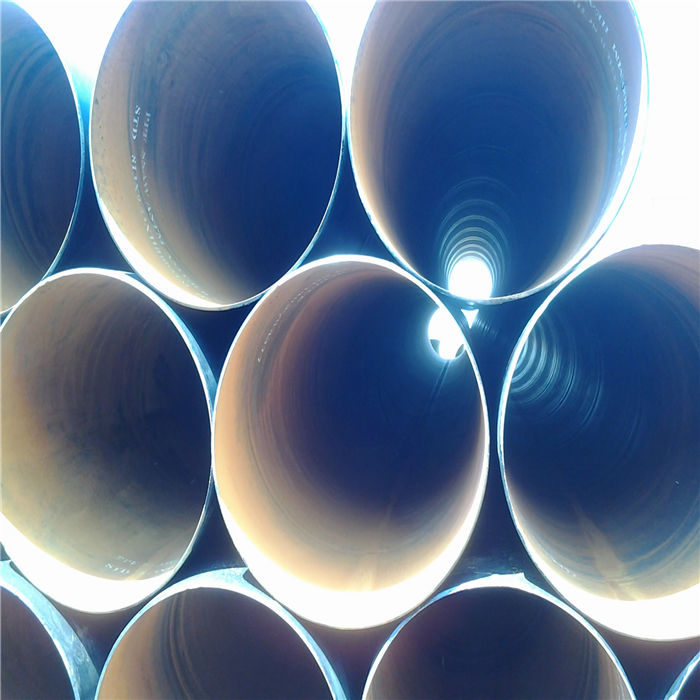

ERW (Electric Resistance Welding Pipes) pipes are manufactured using steel coils: the coil is first uncoiled, smoothed, cut, and finally formed into a round pipe and straight seam welded by high-frequency electricity. ERW pipes are available in sizes between ½ inch and 20 inches (12mm to 508mm) and rapidly becoming a popular alternative to seamless pipes, both in terms of price and performance.

ERW Pipe is a cost-effective alternative to seamless pipes and more durable than SAW pipe. Defects are also less likely to occur compared to the solvent process used in SAW pipe, and the straight weld defects can easily be detected using ultrasonic reflection or by sight.The diameter of ERW pipe ranges from ½ inches (15mm) to 24 inches (21.34mm).

ERW pipes are widely used in aviation,aerospace,energy, electronics,automotive,light industry and other industries.