Hangang ultra-low temperature toughness wear-resistant steel used in green energy coal mining equipment manufacturing

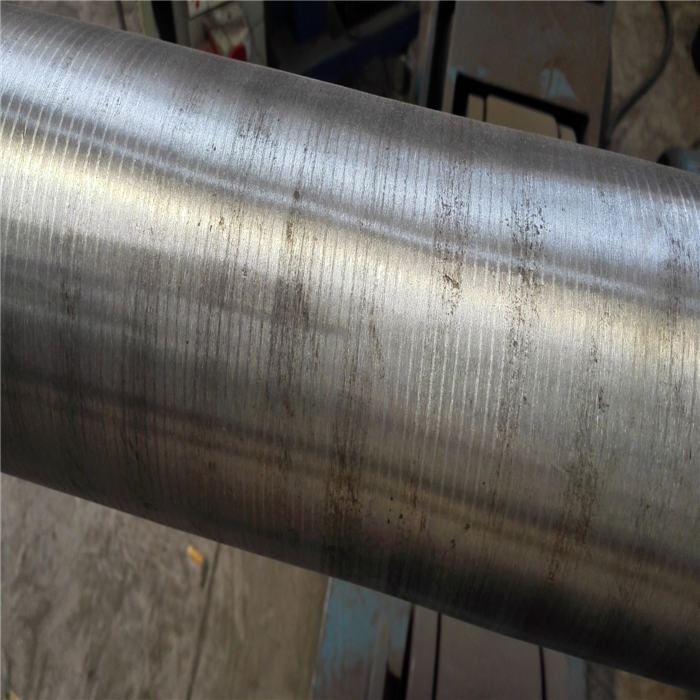

The first batch of high-tech new products developed by Hesteel Group Handang Company, ultra-low temperature toughness wear-resistant steel NM450E-NY, was delivered to customers. The product is strong and well-matched, and the ultra-low temperature impact value of minus 40 degrees Celsius reaches 44 joules to 107 joules, and the quality fully meets customer needs. The product will be used in the manufacture of green thermal coal mining and transportation equipment, and the finished product will be exported overseas.

This customer's green thermal coal mining equipment required steel chemical composition C, P, S and other content are stricter than the national standards, especially the strength, elongation, minus 40 degrees Celsius ultra-low temperature toughness and other requirements. The technical marketing team of Hangang wear-resistant steel developed ultra-low temperature toughness wear-resistant steel NM450E-NY through flexible regulation and quenching process, pressure stabilization of large Angle grain boundary ratio of martensite and the proportion of slats. In the process of research and development, the technicians optimized the production control scheme of low P and low S, strengthened the control of edge cracks and center segregation of the billet, and improved the quality of the billet. The austenite homogenization temperature, temperature control quenching, interval cooling and other processes are used to strengthen the control of key process parameters such as the temperature of the quenching holding section and the cooling speed, so as to ensure that the tensile strength, elongation, ultra-low temperature toughness and surface quality of the offline products meet customer requirements.

Handan Steel continues to increase wear-resistant steel product research and development and market expansion efforts. The new wear-resistant steel NM500-DBJ custom-developed by Hangang successfully replaced imported products and was used for manufacturing key parts of high-end hydraulic balers; Custom developed characteristic wear-resistant steel NM450Tuf instead of imported products, used for large-scale mine sand discharge engineering machinery blade manufacturing.