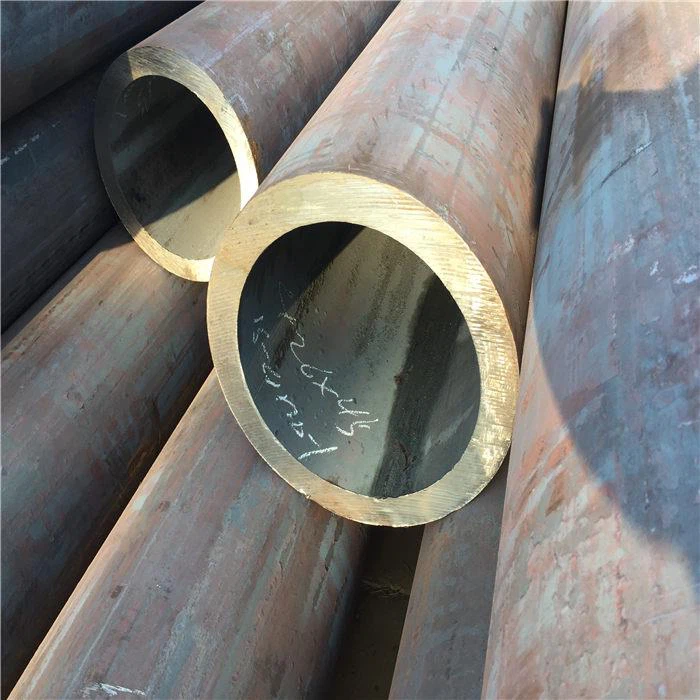

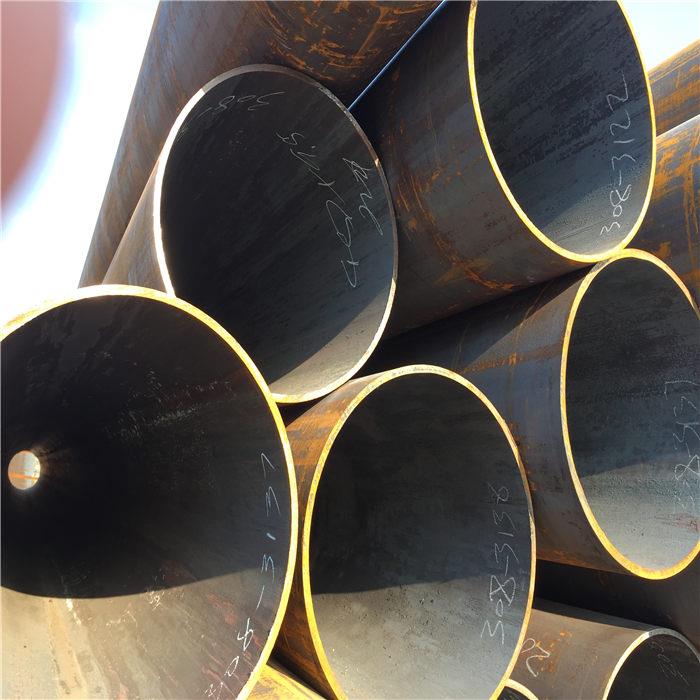

610mm SCH 140 Seamless Line Pipe

Seamless PipeWhat is seamless pipe? Seamless pipe is produced in sizes from 1 8 to 36 " nominal Seamless pipe ha

Product Introduction

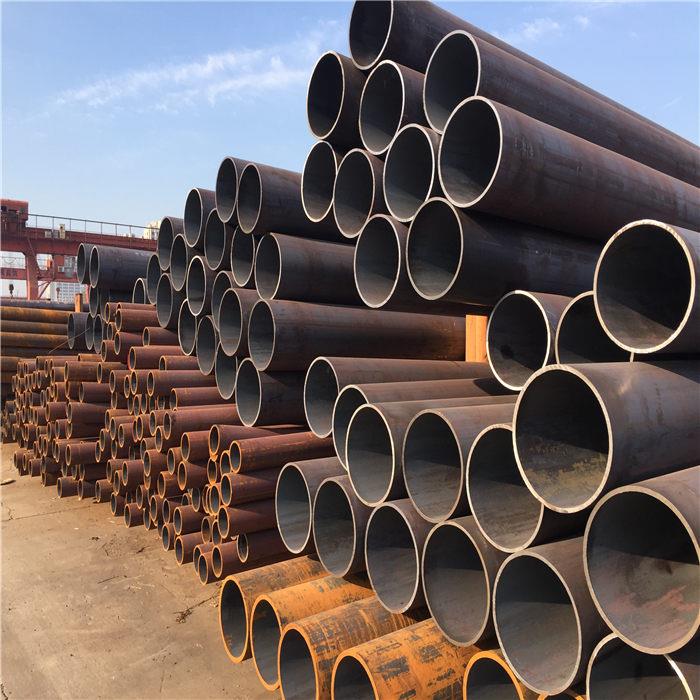

Seamless Pipe

What is seamless pipe? Seamless pipe is produced in sizes from 1/8 to 36" nominal. Seamless pipe has no longitudinal seam or weld when compared to ERW pipe. In simple terms the seamless pipe is produced by piercing a solid round billet leaving behind a hollow seamless pipe. There are two main methods of producing seamless pipe;

-

Hot Rotary Piercing

-

Extrusion Process Method

In Extrusion Process, hot billets of metal are formed into seamless pipe by forcing the billets through extrusion dies and over a forming mandrel.

Hot rotary piercing method is the most common process of producing seamless pipe. In this process hot billets are forced through rotating heavy rollers over a mandrel or piercing plug. The piercing plug creates the hole through the seamless cylindrical billets.

Seamless pipe goes through various finishing operations such as straightening, inspection, hydro testing and imaging. Seamless pipe is widely used in pressure piping, construction, petrochemical and oil refineries. Seamless pipe is available in following specifications;

ASTM A53, A106, A252, A333, A335, A501, A523, A589, API 5L and API 5CT. Most common seamless pipe is A106B and API 5L B

End finish of seamless pipe include plain ends either beveled or square cut. Seamless carbon steel pipe is available in black, bare, galvanized or with epoxy coating.

Steel Pipe Lengths

Generally steel pipe is supplied in 21 ft lengths. It is also available in Single Random Length (SRL) which could be anywhere from 16 ft to 21 ft. Double Random Length (DRL) refers to pipes that is at least 35 ft long and up to 42 ft.

Steel Pipe End Finish

There are five common type of metal pipe end finishes;

-

Threaded and Coupled

-

Threaded without Coupling

-

Plain End - Cut Square

-

Beveled for Welding - 30 deg bevel

-

Grooved End - Cut or rolled for mechanical coupling

Coupling for extra strong and double extra strong pipe are taper threaded and recessed for all sizes.

Most common pipe end type is plain end of beveled end. Threaded ends are also available upon request

Steel Pipe Identification And Marking

Steel pipes is available in different classification, grade, weight, schedule number etc. Hence it is important to identify steel pipe marking. Steel pipe is identified by paint stencil or stamped marking on the pipe itself or by a tag attached to it.

Steel Pipe Material

Metal Pipes are available in following material grades;

-

A106B/A53B/API 5L-X42/API 5L B

-

Stainless Steel 304

-

Stainless Steel 316

-

Super Stainless A20

-

Duplex Stainless D2205

-

Nickel Alloy A200

-

Nickel Alloy A400

-

Nickel Alloy A600

Galaxy Company Hot Sale Steel Pipe Products:

OCTG, casing, tubing, seamless steel pipe, line pipe, boiler tube, ASTM A333 pipe, ASTM A335 alloy pipes, API 5L pipe,, welded steel pipe,LSAW pipes, steel pipe inventory, Chinese pipe factory, API 5L X52 pipe, pipe fittings, API 5CT pipe, Steel pipe, stainless steel pipes.

You Might Also Like

-

large diameter Seamless Line Pipes API 5L GR.B 1016x25.4 mm 6 m length

-

St37 Seamless Tube 88.9mm Diameter

-

Seamless Steel Pipe ASTM A106 B NACE MR 0175 12IN SCH160

-

Seamless Line Pipe API 5L GR.B 24INCH SCH40 12M Length

-

Seamless Pipe 2inch Idimeter XXS 6 M LENGTH Export

-

Seamless Pipe ASTM A106 C 10IN Diameter XS 12M Length

Send Inquiry