The first "green rail" has been produced at the Donawitz plant of Austria Steel.

The official announcement from Steelmen stated that its Donawiz plant has produced the first "green rail", which has been laid at Linz Central Station in Austria. This rail is made from scrap steel and hydrogen directly reduced pure iron (HYFOR technology), and the entire production process achieves complete zero use of fossil fuels and nearly zero carbon dioxide emissions.

Austeel stated that, like the rails produced by conventional processes, the rails made from hydrogen direct reduced iron have high hardness and good wear resistance. At present, the Railway Systems subsidiary of SteelLink can provide services such as track systems, turnout systems and signal technology, including both "hardware" (rails, turnouts, supports and sleepers) and "software" signal technology, offering all-digital monitoring applications for railway lines and trains. Starting from 2027, one green electric furnace has been put into use at each of the Linz and Donawitz plants under Voestalpine. Voestalpine aims to achieve net-zero emissions from steel plant operations by 2050. For this reason, Austeel has begun to research several new processes and has launched pilot and demonstration operations.

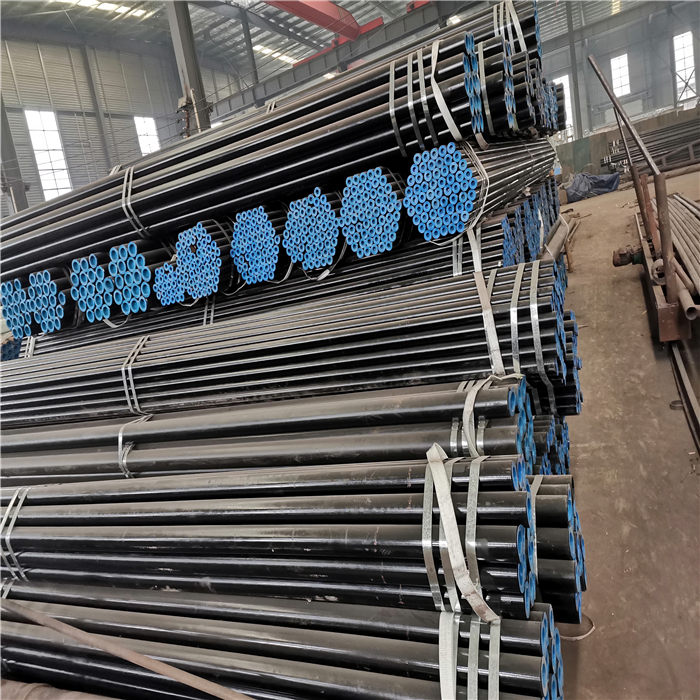

My company hot sale seamless steel pipes:

ASTM A106 B seamless pipes,(1” to 24” sch40, sch80),

API 5L GR.B steel pipes, (seamless pipe, 1” to 30” sch 40, sch80),

Boiler tubes,( 20G. 12Cr1MoVG, ASTM A335 P5, P9, P11),