Jindar Steel Oman Company plans to build its second direct reduction iron plant

Jindal Steel Duqm announced that it plans to build its second hydrogen direct reduction iron plant in Al Wusta, the central province of the Sultanate of Oman, which is scheduled to be put into operation in 2026.

This new direct reduction iron plant will adopt the direct reduction technology (Zero Reformer Energiron®) jointly developed by Tenova and Danieli, with an annual designed production capacity of 2.5 million tons and an average metallization rate of 94%. The products are mainly hot-pressed block iron suitable for storage or export. The products of this direct reduced iron plant will adopt the Hytemp® pneumatic conveying system to directly feed the hot direct reduced iron above 600 degrees Celsius into the electric arc furnace, making the entire production process highly efficient and energy-saving. One of the features of this direct reduction technology jointly developed by Tenon and Danieli is the use of a mixed gas reducing agent. Factories equipped with this technology can produce using natural gas with a hydrogen content as high as 80%, or a mixture of the two in any proportion, without the need to modify the equipment.

This project will utilize the natural gas and renewable energy of the Sultanate of Oman to produce hydrogen. Meanwhile, the project will embed carbon capture facilities into the direct reduction iron plant to comprehensively utilize the captured carbon dioxide, and will be integrated into the larger green steel complex of Jindal Steel Oman.

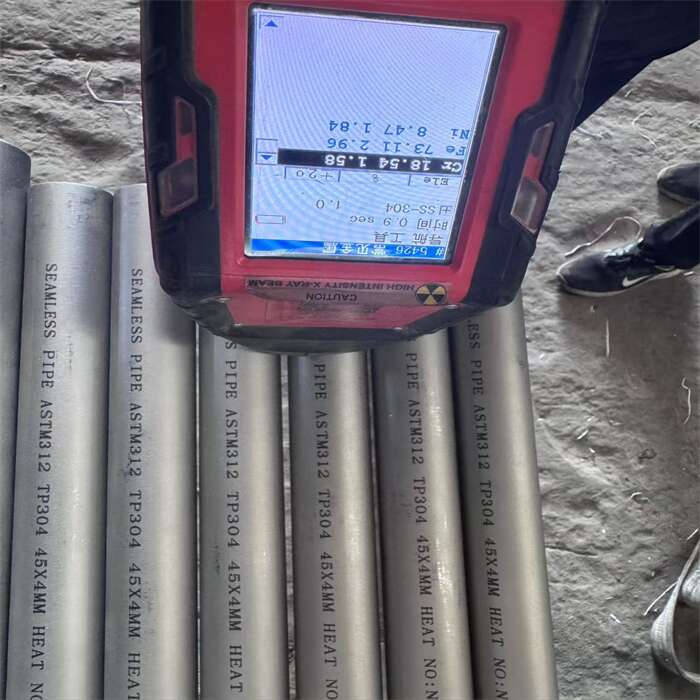

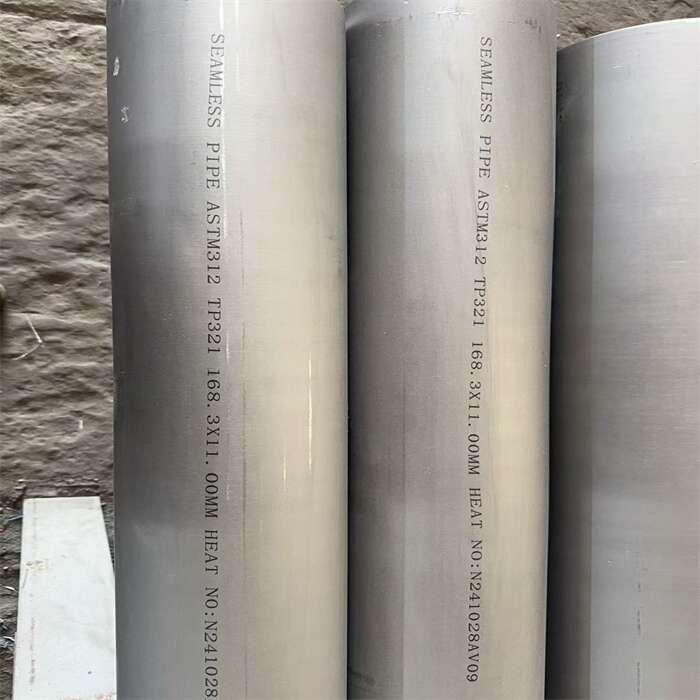

My company hot sale stainless steel pipe:

TP304/304L, TP316/TP316L, TP347, stainless steel welded Pipes, stainless seamless pipes, stainless steel welded and seamless pipes, (1” to 48” sch10, sch20, sch40, sch80)